2025-07-07

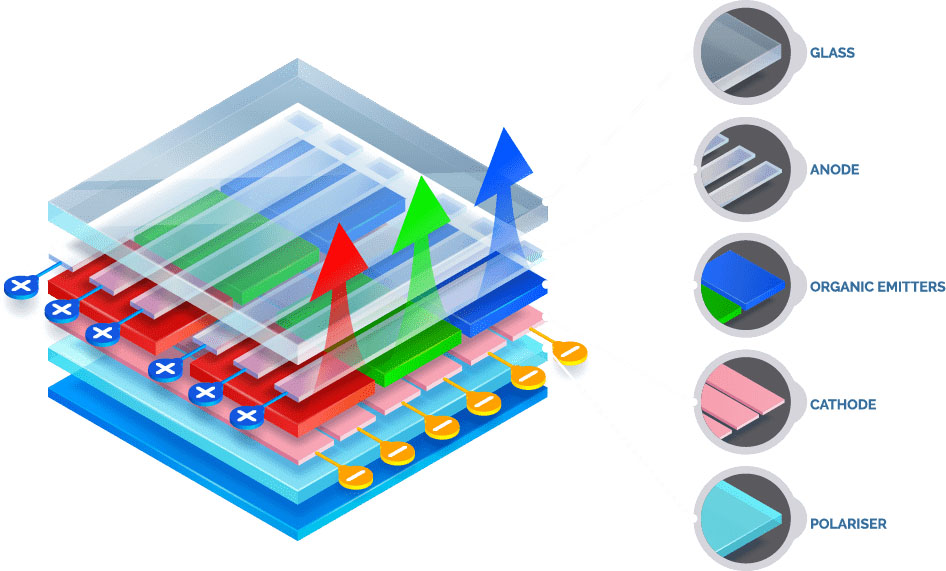

OLED pixels are true self-emissive light sources rather than transmissive layers over a backlight. In a typical (bottom-emitting) OLED structure, a transparent substrate with its anode and driving TFT array is topped by multiple organic thin films and a reflective cathode. When voltage is applied, electrons from the cathode and holes from the anode migrate into the organic stack and recombine in the emissive layer, forming excitons that relax by emitting photons. In practice, the emissive layer is a host matrix doped with color-emitting molecules, so that electrical energy converts directly into red, green, or blue light. The diagram below shows this multilayer stack: anode, hole-transport layers, the doped emissive layer, blocking/transport layers, and cathode. After fabrication, the full organic stack is encapsulated under thin barriers to protect it from moisture.

Some OLED designs instead emit through the top side. In a top-emitting OLED (TE-OLED), the usual transparent anode is replaced by a reflective metal electrode, and the cathode is made thin and semi-transparent so light can exit from above. This avoids sending the light through the opaque silicon backplane, improving light extraction. Top-emitting OLEDs are used in high-resolution or flexible panels where the backplane can’t be transparent. Light simply leaves the device on the cathode side in a TE-OLED, which can make the panel slightly more efficient than the bottom-emitting version.

A hallmark of OLED displays is their extraordinarily high contrast. Because each OLED pixel can be turned completely off, an OLED can display true black (0 nits) in dark areas. OLEDs are often said to have a technically infinite contrast ratio, since the brightest white divided by absolute zero light is infinite. The practical effect is stunning: pitch-black scenes on an OLED have no glow, enabling HDR video with very vivid highlights and deep shadows. Bright objects “pop” against a completely dark background without any backlight bleed.

For everyday content, this contrast also yields benefits. Dark-themed UIs on phones or dark clothes in a movie look richer on OLED. It also influences power use: darker pixels consume significantly less energy on OLED than bright ones. OLEDs use proportionally more power for large white or bright areas and far less for black content.

OLED pixels turn on and off extremely quickly, which enables very high refresh rates and minimal motion blur. The organic layers respond in microseconds, orders of magnitude faster than LCD crystals.

Consumer OLED panels routinely support 120–240 Hz refresh rates. High-end OLED gaming monitors now offer 240 Hz refresh at 0.03 ms gray-to-gray response time, delivering virtually instantaneous frame updates. This makes fast motion (gaming, sports) exceptionally clear on OLED: there is no perceptible smearing or “sample-and-hold” blur.

With no backlight, an OLED’s power draw depends directly on what is lit on screen. Dark or black pixels consume almost no power, while bright pixels draw more current. For instance, switching a phone UI to a dark theme can cut display power by as much as 40% in outdoor conditions. In contrast, an LCD’s backlight costs nearly the same energy no matter what is on screen. OLED allows techniques like dark-themed interfaces to improve battery life while also enhancing contrast. Designers can also dynamically dim or turn off unused pixels to save energy.

An attractive feature of OLED is its physical flexibility. Because all layers are thin films (often deposited on plastic or metal foil), OLED panels can be bent or rolled. In principle, an OLED display can even be made transparent or see-through. Current OLED devices include foldable smartphones and rollable TVs, as well as OLED-based fingerprint scanners under phone glass.

Flexible plastic OLED screens have already shipped in consumer products. The entire organic stack is encapsulated under a protective multilayer barrier film or lamination. This barrier keeps the device waterproof yet leaves it thin and pliable.

The flip side of OLED’s organic materials is that they degrade over time. The most notorious issue is the limited lifetime of the emitters, especially blue. Historically, blue-emissive materials had much shorter lifespan and lower efficiency than red/green. This can lead to color shifts and uniformity changes as a panel ages. A related problem is image retention or burn-in. Modern OLED systems mitigate this with software and hardware solutions, but the underlying vulnerability remains.

OLED’s organic layers are also chemically sensitive to moisture and oxygen. If air penetrates the encapsulation, dark spots or complete failure can occur. Thus, careful sealing of the stack is crucial. While OLED panels offer stunning image quality, they require strict isolation and can suffer finite lifetimes (though modern designs now reach tens of thousands of hours with careful control).

To push OLED brightness and longevity, engineers have turned to tandem structures. A tandem OLED stacks two (or more) full RGB-emissive layers in series per pixel. Each layer emits its own light, so combining them yields much higher total luminance. Some OLED panels use a dual-stack RGB layout: two OLED stacks share the same pixels but each only runs at moderate current. This roughly doubles the panel lifetime and triples peak brightness compared to a single layer. Tandem OLEDs also save power: driving two layers at half the brightness is more efficient than one layer at full brightness. In effect, tandem designs deliver exceptional HDR brightness and extend display life.

Quantum-dot OLED (QD-OLED) is another recent hybrid that fuses OLED contrast with quantum-dot color. In a QD-OLED panel, the backlight is a pure blue OLED emitter. Its blue light strikes tiny quantum dots or patterned QD films that down-convert part of the spectrum into pure red and green. In this way, all three colors are generated with minimal organic layers. The result is extraordinarily wide color gamut and high brightness. QD-OLEDs can produce more vivid colors and higher color volume than previous OLEDs, yet they still enjoy OLED’s perfect blacks and fast response.

OLED technology is rapidly entering its next stage. We already see OLED panels in smartphones, TVs, monitors, laptops, and head-mounted displays, and usage will only broaden.

On the consumer side, expect ever more innovative form factors: rollable and foldable tablets and phones, transparent displays in cars or appliances, and wearable OLEDs in glasses or clothing.

In professional markets, OLED’s extreme color accuracy and contrast make it ideal for film editing, medical imaging, and other fields requiring faithful image reproduction. Technical trends will yield even brighter, longer-lasting panels. OLED is poised to become ubiquitous in both consumer gadgets and professional equipment, evolving into larger panels, smaller pixels, and entirely new applications in the coming years. For those comparing different panel architectures, a detailed analysis of IPS and OLED Displays reveals key differences in structure, performance, and application suitability.

MICRON delivers cutting-edge solutions based on copper metal mesh technology, including touch films, transparent antennas, transparent heating films, and EMI shielding films. Holding over 60% of global patents in metal mesh technology, we are committed to innovation, backed by a dedicated R&D team and stringent quality control to ensure product durability and reliability.

As a trusted supplier to leading global touch device manufacturers, MICRON has established subsidiaries in countries such as the United States and Japan to provide timely and efficient services worldwide, ensuring seamless support for our international clients.