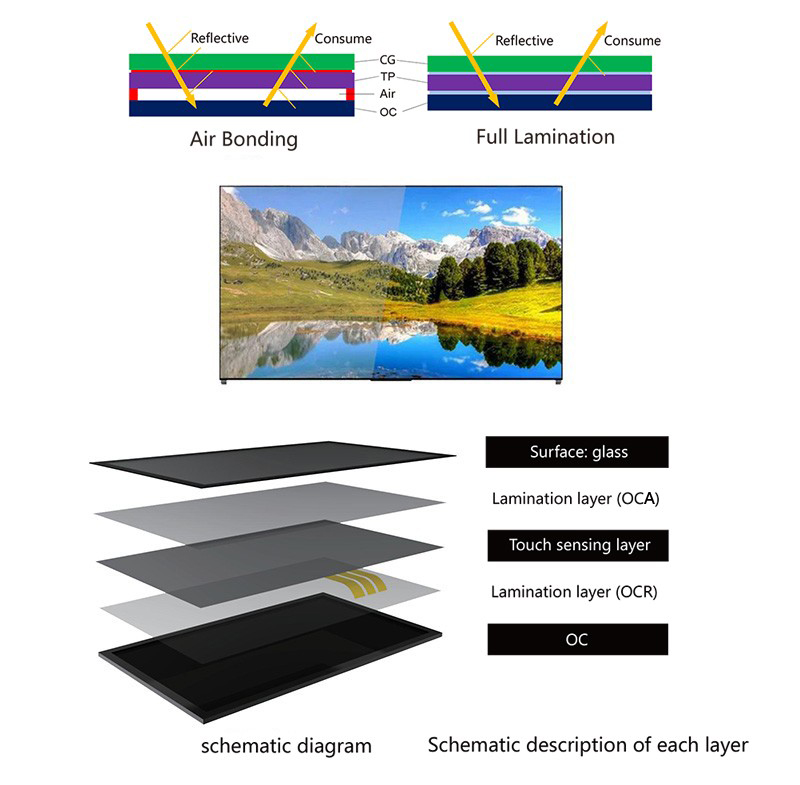

Full lamination is to completely glue the glass cover, display panel and touch screen together in a seamless manner with water glue or optical glue material.

Compared with the traditional common lamination technology “frame sticker”, it can provide better optical display effect and ultra-thin appearance design.

The full lamination omits the air layer between the display screen and the touch screen, making the screen thickness thinner, making the visual effect perfectly presented, looking more beautiful, reducing the probability of gray entry, making the picture more transparent and enhancing the display At the same time, it also makes the screen thinner; it seems that the full-fit is more aesthetically pleasing and practical; but the full-fit technology has a low yield rate and relatively high cost, and once damaged, the entire screen needs to be replaced.

Adopt “full lamination process”. The air layer between the display screen and the glass is fundamentally eliminated, so that the liquid crystal panel and the glass are closely attached to prevent the intrusion of dust and water vapor, so that the screen is always in an excellent state of use. At the same time, it can reduce the reflection of external light, increase the transmission of the display screen and improve the brightness, so that the picture is clearer and more thorough. It can still provide excellent display effect under strong light or direct sunlight. In addition, the full lamination process makes the LCD screen and the capacitive screen fit perfectly, so as to achieve more precise touch operation.

The frame-mounted display screen uses double-sided tape to fix the touch screen and the four sides of the display panel. There is an air-filled gap between the display panel and the touch screen. The operation is relatively simple and the process is relatively mature.

Mature craftsmanship and stable yield give frame stickers the biggest advantage. It is cheaper and easier to replace. Another feature of it is that the screen is thick, and the overall body cannot be thin and light.

There are gaps, and dust is the biggest enemy of existence; in addition, the panel and glass of the frame stickers are more reflective, and the display effect is relatively poor.

OCR is a water glue, which belongs to the UV light series glue. UV is written by the English Ultraviolet Rays, that is, ultraviolet light, with a wavelength in the range of 10-400nm.

UV glue is also known as shadowless glue, photosensitive glue, UV curing glue. A class of adhesives that must be cured by exposure to UV light.

The curing principle of UV glue: the photoinitiator (or photosensitizer) in the UV curing material absorbs the ultraviolet light to generate active free radicals or cations under the irradiation of ultraviolet light, which initiates the polymerization, cross-linking and branching chemical reactions of the monomers. The mixture changes from liquid to solid in seconds.

The product adopts the TP+OC bonding method, the surface layer is TP, and the bottom OC is bonded by OCR water glue.

After years of precipitation and accumulation, our company has complete equipment, mature technology, and a complete R&D and production system to provide customers with overall solutions. According to design plans and requirements, we provide personalized customized fitting services. We always adhere to customer Oriented, tailor-made the best solution for customer needs.