2025-07-04

An IPS (In-Plane Switching) display is a type of liquid-crystal display (LCD) panel technology. In an IPS panel, the liquid-crystal molecules lie flat in the plane of the glass substrates. When a voltage is applied, these molecules rotate in-plane to change the polarization of light, thus forming the image. This differs from older LCD designs and was introduced in the mid-1990s to greatly improve color fidelity and viewing angles. In practice, an IPS module consists of an LED backlight, two crossed polarizing films, color filters for RGB subpixels, and a layer of horizontally aligned liquid crystals controlled by an array of thin-film transistors (TFTs).

Historically, IPS technology was first patented in 1990. The first commercial IPS panels appeared around 1996. Over the 2000s, several improved IPS variants were developed, including S-IPS (Super IPS), H-IPS and AH-IPS (Advanced High-performance IPS), P-IPS (Professional IPS), and Nano IPS. Nano IPS applies nanometer-scale particles to the LED backlight to expand the color gamut and improve saturation and vibrancy. These innovations have made IPS the dominant technology in color-critical and angle-sensitive applications.

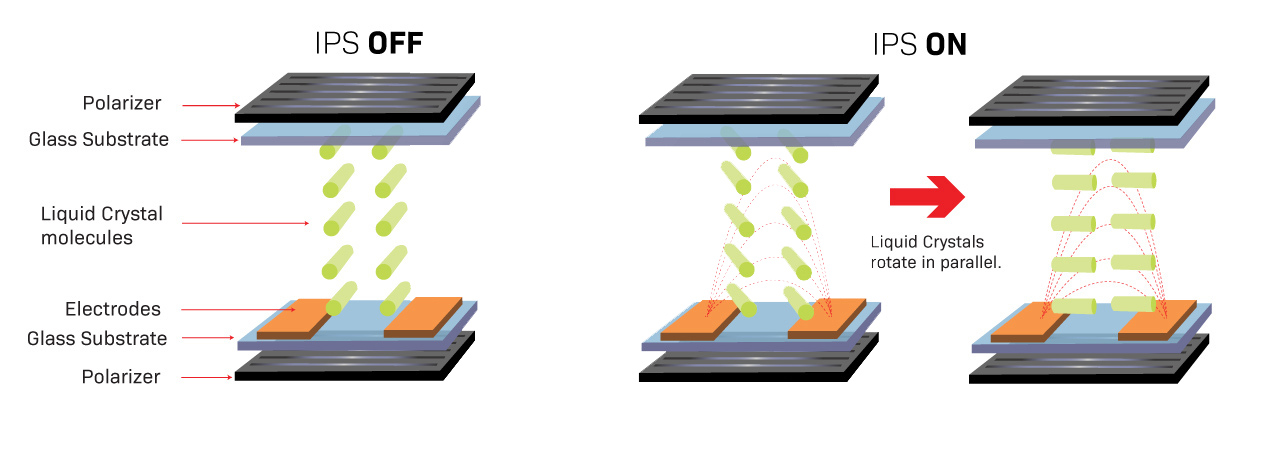

The core of an IPS display is the TFT-LCD cell. A white LED backlight shines from behind the glass. Its light first passes through a linear polarizer. The polarized light then enters the liquid-crystal (LC) layer. These liquid crystals are rod-shaped molecules initially aligned parallel to the glass surfaces. When no voltage is applied, the LCs maintain a twisted alignment that blocks most light from reaching the second polarizer. When a voltage is applied across an LCD cell, an electric field causes the LCs to rotate in their plane by up to 90°. This rotation changes the polarization of the light passing through. The light then encounters the second polarizer (usually crossed at 90° to the first), which only transmits light of a particular polarization. Finally, the polarized light goes through the RGB color filter layer, and each subpixel transmits its respective color component.

In an IPS panel, the two polarizers are parallel, and the electrodes generating the field are co-planar on one substrate. This means the electric field is entirely in the plane of the glass, so the crystals rotate sideways rather than tilting upright. The result is a very uniform crystal alignment even at wide viewing angles. This structural design is the key to IPS’s distinctive color and angle performance.

Several evolutions of IPS have been developed, each with trade-offs in cost, performance, and power:

– S-IPS (Super IPS): The original improved IPS, offering better color shift and refresh performance.

– H-IPS / AH-IPS: Introduced higher resolutions, better brightness, and improved power efficiency.

– E-IPS: A cost-effective variant with improved viewing angles and response times.

– P-IPS: Designed for ultra-high color depth, enabling true 10-bit color.

– Nano IPS: Enhances the color gamut using nanometer particles to filter light precisely.

Despite different brandings, all share the in-plane switching principle and aim to preserve wide viewing angles and color fidelity.

1. Wide Viewing Angles: IPS panels maintain consistent color and contrast when viewed from extreme off-center angles (often specified as ~178° horizontal and vertical). Colors and brightness remain virtually unchanged even tens of degrees off-axis. This is critical in multi-user or public-display situations, and it eliminates the color shift or washout seen in simpler LCDs.

2. Accurate Color Reproduction: Thanks to the parallel crystal alignment and high bit-depth driving, IPS panels produce very accurate and stable colors. Many IPS displays support true 8‑bit or 10‑bit color depth (16.7 million to ~1 billion colors), and they often cover wide color spaces (professional models can hit near-full Adobe RGB or DCI-P3 gamut). This makes IPS the preferred choice for graphics workstations, video editing, and any application where color fidelity is essential.

3. Consistent Image Quality: IPS panels exhibit minimal “inversion” or grayscale shifts. They do not brighten or dim simply due to slight changes in viewing direction. Text and graphics stay sharp and free of color tint at all angles. Moreover, IPS does not suffer from the “ghost touch” or tailing seen in some other panels when pressed or in motion.

4. Good Performance in Bright Environments: Modern IPS monitors use bright LED backlights and do not degrade much under ambient light. Combined with their wide angles, IPS displays often out-perform other LCDs in bright or direct-light conditions. This makes them suitable for rooms with windows or outdoor kiosks (with adequate high-brightness panels).

5. Evolving Response and Refresh: While early IPS had slower transitions, today’s IPS panels can be very fast. High-end IPS gaming monitors now achieve 120–240 Hz refresh rates and gray-to-gray response times down to ~1 ms. Specialized IPS (like Nano IPS) use overdrive circuitry to cut ghosting to levels once only possible on TN panels. For most office and creative applications, IPS responds quickly enough to render video and animations smoothly.

6. High Contrast and Black Stability: Standard IPS contrast ratios are moderate (typically ~1000:1). Blacks on IPS are generally stable and do not invert color, though they may appear a bit “glowy” at extreme angles. Overall image contrast is adequate for most tasks. (For reference, some IPS variants include local-dimming backlights or mini-LED behind them to boost HDR contrast.)

Graphic designers, photographers, videographers and broadcast professionals use IPS monitors to view and edit content. IPS panels’ support for wide color gamuts (Adobe RGB, DCI-P3) and 10-bit color makes them ideal for ensuring on-screen colors match printed or filmed output.

Workstation displays, color-graded video monitors, and any application needing pixel-perfect accuracy typically rely on IPS LCDs.

In factories and plants, human-machine interfaces (HMIs) and control panels often use IPS screens. Their wide angles let operators easily read gauges from the side. Ruggedized IPS modules (with reinforced glass and moisture seals) are available for harsh environments. High brightness and anti-glare variants are used in outdoor kiosks, transportation dashboards, and logistics displays.

Healthcare devices (ultrasound machines, patient monitors, diagnostic scanners) often embed IPS panels. The reasons include the need for accurate grayscale/color rendering, wide viewing (for collaborative diagnosis), and longevity (no burn-in risk).

Digital signage, video walls, and conference-room displays often use IPS LCDs. The consistency of colors across large viewing cones is important for onlookers. Office monitors and laptops broadly use IPS for better user experience compared to cheaper LCD types.

In educational settings (labs, classrooms), IPS panels ensure all students see the same information clearly. Higher-end gaming monitors now often use IPS to combine fast refresh with good color, giving gamers both speed and visual quality.

Virtually all modern smartphones, tablets, and laptops adopt IPS or IPS-derivative screens due to their balanced performance. Even in TVs, many mid-range models use IPS LCD panels (often with quantum-dot enhancement) to deliver wide color and viewing angle.

While IPS offers many advantages, there are trade-offs:

1. Power Consumption: IPS panels require more power than simpler LCDs. The in-plane electrode structure and larger backlight often draw ~10–20% more power than older TN panels. In battery-powered or low-power applications, this extra draw must be managed (e.g. by using dimming or efficient LEDs).

2. Cost: The manufacturing process for IPS (multiple thin-film transistors per pixel, precise liquid-crystal alignment) is more complex. As a result, IPS LCD modules tend to cost more than TN LCDs or some VA panels. High-end variants (e.g. 10-bit or Nano IPS) carry a premium price, reflecting their specialized materials (polarisers, nanoparticles) and calibration.

3. Panel Thickness and Complexity: An IPS display stack (multiple glass substrates, polarizers, LEDs) cannot be made as physically thin as, say, an organic LED panel. A typical IPS monitor panel may be several millimeters thick, plus space for mounting and cooling. Designers must account for this thickness, weight, and heat dissipation in product integration.

4. Response and Ghosting: Although modern IPS can be fast, they still generally have slower liquid-crystal switching than the absolute fastest LCDs. Without overdrive, native grey-to-grey times were often 5–8 ms. In extreme high-speed applications (e.g. competitive gaming), this could cause slight motion blur. Manufacturers combat this with overdrive circuits and backlight strobing. (Early IPS monitors had >10 ms response, but recent models boast 1–4 ms GTG with proper driving.)

5. Contrast and Black Depth: IPS panels do not achieve the highest contrast ratios among LCDs. Their blacks may appear a little grey in very dark scenes, and small-angle “IPS glow” can make black levels non-uniform. In most bright or office environments this is acceptable, but it is a factor in, e.g., dark-room viewing.

6. Manufacturing Defects: Like all LCDs, IPS screens can show defects like stuck pixels or slight backlight bleed. IPS-specific issues include slight uniformity tolerances – for critical use, buyers often specify high-grade industrial panels with tight quality control.

An engineer should weigh power, cost, and physical constraints when choosing IPS. But for most professional and industrial uses, the trade-offs are acceptable given the clear image quality benefits.

This is the color precision per subpixel. Common IPS monitors are 8 bits per channel (RGB), yielding 16.7 million colors. Some professional IPS panels use 10 bits per channel (1.07 billion colors) with true 30-bit input. (Less expensive panels often use 6-bit cells with FRC dithering to simulate 8-bit.) Higher bit depth reduces color banding and allows coverage of wide gamuts.

The number of times per second the display image is redrawn (in hertz, Hz). Standard monitors run at 60 Hz (60 frames per second), but many IPS displays now support 75, 120, 144, or even 240 Hz. A higher refresh rate can smooth motion and reduce input lag. Modern IPS gaming monitors commonly operate at 120–240 Hz, narrowing the gap with fast-response panels.

Often specified in milliseconds (ms), this measures how quickly a pixel can change from one intensity to another (typically from one gray level to another). For example, a 5 ms GTG spec means a pixel needs 5 ms to go between those gray levels. Faster response time means less motion blur. Early IPS panels might have been 10+ ms, but today’s IPS can achieve ~1–4 ms with overdrive. (Manufacturers usually quote GTG; note that human perception of motion blur also depends on refresh rate and pixel persistence.)

The range of colors a display can produce. Common standards include sRGB (for web) and DCI-P3/AdobeRGB (for film/photo). IPS displays typically cover around 100% of sRGB. Enhanced IPS variants and Nano IPS can cover ~98% DCI-P3 or more. Wide-gamut IPS panels are preferred for color-critical tasks, and many high-end monitors offer user-selectable color modes (sRGB, AdobeRGB, etc).

The ratio of the brightest white to the darkest black the panel can produce. Typical IPS panels have ~1000:1 native contrast. (Since they use a backlight, blacks are never absolute 0 nit.) Advanced versions may implement dimming zones or local dimming (with Mini-LED backlights) to improve effective contrast in HDR mode.

Usually quoted as the angle (horizontal/vertical) at which contrast falls to half. IPS panels often list “178°/178°” indicating very wide angles. In practice, this means the image remains legible and colors stable almost edge-on.

Understanding these terms helps in evaluating an IPS display’s performance specifications and ensuring it meets project requirements. Choosing the right display technology is just as important, such as IPS and OLED Displays.

MICRON delivers cutting-edge solutions based on copper metal mesh technology, including touch films, transparent antennas, transparent heating films, and EMI shielding films. Holding over 60% of global patents in metal mesh technology, we are committed to innovation, backed by a dedicated R&D team and stringent quality control to ensure product durability and reliability.

As a trusted supplier to leading global touch device manufacturers, MICRON has established subsidiaries in countries such as the United States and Japan to provide timely and efficient services worldwide, ensuring seamless support for our international clients.