2022-08-16

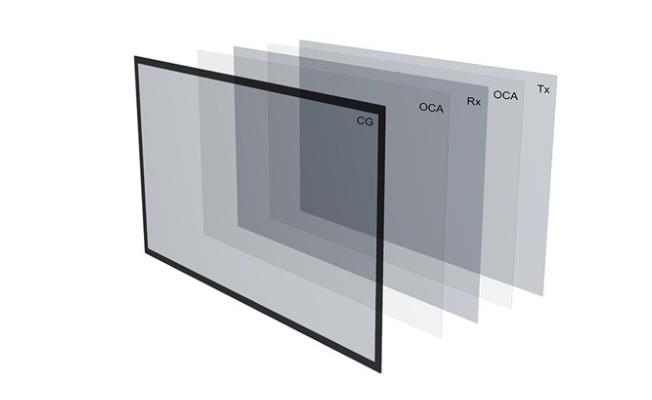

An OCA is a laminated film used as a barrier between two layers of paper or plastic. It prevents moisture from penetrating through the material. The touch panel displays of mobile phones or tablets may be repaired with the OCA lamination machine. It switches, assisting the device in effectively completing the required duty to repair the damaged screen panel or screen. The machine has a variety of uses.

OCA film often referred to as soft-to-soft bonding, is shown on the sensor function sheet. OCA attachment equipment that is semi-automatic is typically utilized. The attachment is finished after the equipment is automatically aligned. The sensor is manually placed on the equipment table, the isolation paper on the upper layer of the OCA is manually torn off (it can be pasted with a small piece of tape, which is more convenient), and then the attachment is completed.

The OCA Soft-to-Soft Lamination (FF) is a new type of laminate flooring that offers the best combination of comfort and durability. A laminated floor is made up of several layers or plies of material. Each ply has its own properties, including density, thickness, and strength. These properties help determine the quality of the laminate flooring product. OCA Soft-To-Soft feature allows creating of a more durable product, saving you time and money.

We are always looking to improve our products to increase efficiency and reduce costs, so here’s another great way we’re doing just that.

The technique of glueing two or more pieces of soft material together using OCA is known as soft-to-soft lamination (FF) (Optically Clear Adhesive). Usually, this method is used to bond LCDs, touchscreens, and other delicate electronic parts to one another or to other substrates. Because it produces a powerful connection between the two materials while yet allowing for some flexibility, this method is frequently employed when dealing with LCDs and touchscreens. This is significant because it enables little movement of the LCD or touchscreen without compromising their connection. Numerous other electronic products, including PCs, tablets, and mobile phones, are also made using OCA soft-to-soft lamination.

There are following benefits which are given below:

OCA soft-to-soft lamination (FF) is a high-quality alternative to traditional hardwood flooring. It offers many advantages over conventional hardwood, including increased durability, resistance to scratches and stains, and ease of installation. It is also highly durable and resistant to scratches on touchscreens. That combines the best features of hardwood and is engineered. Its low CRI rating means it won’t overheat your space and its energy efficiency means you will spend less on utilities. It is an excellent solution for those looking for an eco-friendly alternative to hardwood or laminate.

The technology combines the best features of hard and soft laminate. It offers enhanced protection against scratches and stains while maintaining its beautiful appearance. It is a high-quality product that combines the best features of both hard and soft laminate. It has an attractive look and feels as well as excellent wear resistance. It is suitable for indoor or outdoor applications.

They offer a unique combination of high-performance properties and exceptional aesthetics. That allows us to produce high-quality laminated without compromising on durability or performance. With its fantastic variety of properties, OCA Soft-To-Soft offers an excellent solution for applications requiring the highest level of durability. We have developed a new laminating process that combines the best qualities of both traditional hard and soft laminates.

OCA Soft-To-Soft Laminates offer high-quality products with reduced optical distortion. They provide an excellent alternative to hard-coated lenses. These lenses are highly durable and have been used by professionals for years. Soft-to-Soft Laminates are made from two layers of plastic bonded together by an adhesive layer. They are highly durable and resistant to scratching.

A new OCA laminate type has been developed to help reduce the overall surface reflectance. It uses an innovative coating technology that is applied as a low viscosity solution onto the top layer of the OCA substrate using a continuous roll-coating process.

We have developed a type of laminate called OCA soft-To Soft Lamination (FF). It is a great way to increase durability while maintaining its look and feel. It is suitable for both residential and commercial applications. They combine two distinct layers of film, resulting in a superior laminate offering increased flexibility, toughness and performance. The latest innovation from OCA is the addition of a second layer of film on top of the existing one. This means the entire structure becomes softer, making it easier to work with and much more flexible.

OCA soft-to-soft lamination (FF) is a high-quality laminating machine that has been used in the packaging industry. OCA film often referred to as soft-to-soft bonding, is shown on the sensor function sheet. It is also known as a FF laminator. Usually, this method is used to bond LCDs, touchscreens, and other delicate electronic parts to one another or to other substrates. Strong client connections, in our opinion, are essential for business development. Our product is very well-liked by customers due to its superior quality and competitive cost. Anyone can utilize it now that it has been provided. Modern advancements are making their way into our lives as the globe changes. By leveraging cutting-edge technology, we wish to bring everything up to date and make people’s lives brighter than they were before. Must visit our website MICRON. We sincerely hope you enjoyed it after acquiring the magnificent and priceless goods. So do get in touch with us right away. Buy them at this time!