2025-07-09

Liquid Crystal Display (LCD) technology isn’t just prevalent; it’s foundational. For engineers designing systems and procurement specialists sourcing components, understanding the nuances of LCDs is critical. Why? Because they consistently deliver a compelling balance: solid image quality, impressive power efficiency, mature manufacturing, and versatile integration options – a combination that keeps them relevant across countless applications, from industrial HMIs and medical monitors to consumer devices and digital signage.

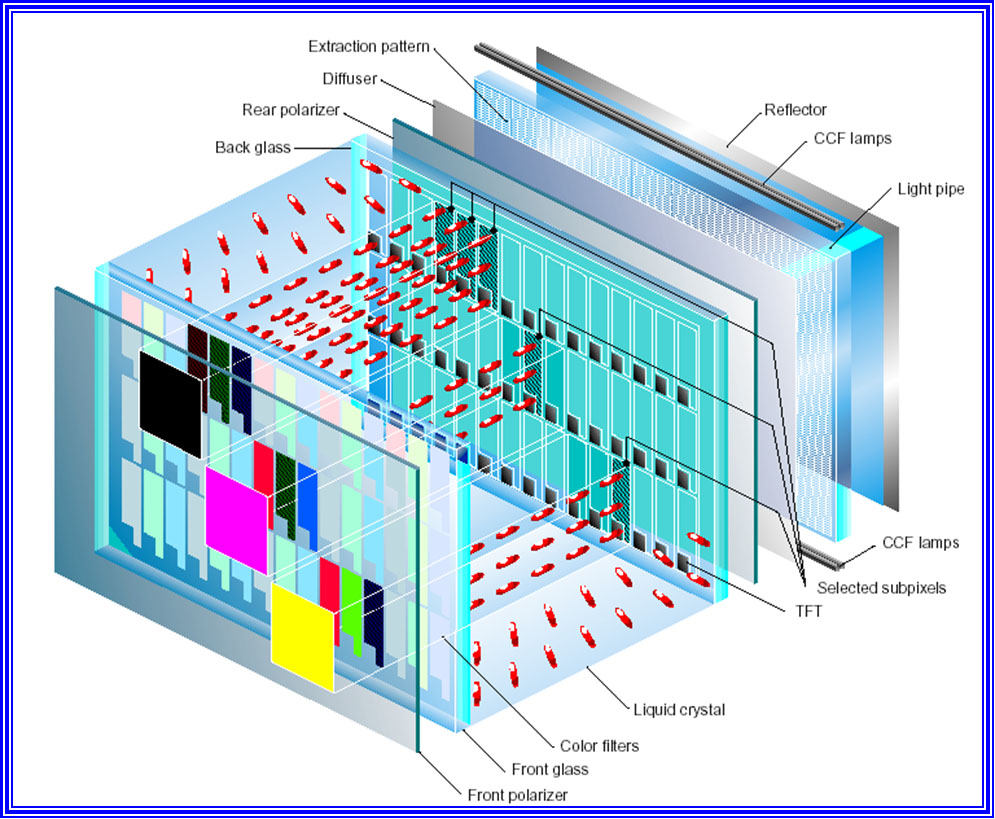

At its core, an LCD panel is a sophisticated light-modulating device, not a light emitter. It relies on a uniform backlight—typically LED-based today—to provide illumination. In front of this light sits a sandwich structure of layers: a linear polarizer, glass electrodes etched on both sides, a liquid crystal layer, and another polarizer. The liquid crystals, initially aligned by microgrooved alignment films, rotate when a voltage is applied. This rotation alters the polarization of light, controlling whether it passes through the second polarizer. As a result, each pixel can be partially or fully transparent, allowing precise brightness modulation for each subpixel. A color filter overlays three subpixels to render full-color images. Thin-film transistors (TFTs) embedded within each pixel maintain these voltage states for crisp, flicker-free images. This active-matrix design allows modern LCDs to handle high resolutions and dynamic content fluidly.

LCD panels offer several engineered benefits and trade-offs:

– Image Quality & Viewing Precision:

Advanced LCD types like IPS and VA provide wide viewing angles (~178°), accurate color reproduction, and contrast ratios around 1000:1. However, they rely on backlight control, which means blacks can appear grayish in low light unless enhanced by local dimming.

– Refresh Dynamics & Response Time:

Modern active-matrix LCDs utilize fast-refreshed TFTs and overdrive circuits to minimize ghosting. Yet display lag can occur from internal processing or scaling. High-refresh variants (~240–480 Hz) cater to gaming and animation-focused use cases.

– Energy Efficiency & Thermal Profile:

LED backlighting systems consume significantly less power than legacy CCFL units, producing minimal heat and supporting high reliability in constrained environments.

– Robustness to Environmental Extremes:

LCDs are generally tolerant to a wide range of temperatures and humidity—but performance varies with backlight design. Proper selection and thermal design are required to mitigate issues like flicker or response lag in harsh conditions.

Different applications influence LCD selection:

Industrial-control panels and HMIs must operate reliably under vibration, temperature fluctuations, and even moisture exposure. Ruggedized, high-brightness LCDs with sunlight readability serve factories, energy systems, and transportation hubs. Medical-grade screens prioritize grayscale precision and DICOM compliance; they often include calibration schemes to maintain consistent imaging over time.

In commercial contexts—such as digital signage or retail kiosks—screen size and visibility drive purchase decisions. Larger formats benefit from higher resolution modules, professional-grade brightness, and precise backlight uniformity. Similarly, education environments leverage LCDs for clarity and cost efficiency in shared settings.

From a sourcing perspective, these selection criteria are essential:

– Form Factor & Connectivity: Choose suitable diagonal sizes, aspect ratios, brightness levels, interface protocols (eDP, LVDS, HDMI), and physical mounting options.

– Quality & Supply Assurance: Opt for panels compliant with defect standards and sourced from diverse fabrication partners. Confirm lifespan, LED backlight ratings, and warranty support.

– Integration Complexity: Review whether modules come open-frame or enclosed with touchscreen overlays. Validate compatibility with system thermal plans to prevent heat-induced pixel or backlight degradation.

– Long-Term Availability: LCD panel models can be discontinued; securing multi-year support or last-time buy options is critical for B2B equipment lifecycles.

– Choice of display technology: The common display technologies on the market are LCD and OLED. You should choose according to the actual usage scenario.

LCD technology continues evolving. Mini‑LED backlights introduce thousands of dimming zones, improving contrast and enabling HDR-quality visuals. Bistable or transflective LCDs, used in outdoor or low-power displays, maintain images with minimal backlight energy. Temporal frame rate control extends color depth beyond native 6-bit cell limitations. While effective, frame-rate control may produce zonal flicker noticeable to sensitive users.

MICRON delivers cutting-edge solutions based on copper metal mesh technology, including touch films, transparent antennas, transparent heating films, and EMI shielding films. Holding over 60% of global patents in metal mesh technology, we are committed to innovation, backed by a dedicated R&D team and stringent quality control to ensure product durability and reliability.

As a trusted supplier to leading global touch device manufacturers, MICRON has established subsidiaries in countries such as the United States and Japan to provide timely and efficient services worldwide, ensuring seamless support for our international clients.