2025-11-27

– Product Design Specification: Touch technology (e.g., PCAP, resistive), dimensions, interfaces, coatings.

– Glass and Sensor Design: Optical clarity, strength, electrical performance, and integration.

– Glass Substrate: Sourced from specialty suppliers (e.g., Corning, Schott, AGC etc.).

– ITO Film or ITO-Coated Glass: For capacitive touchscreens.

– Adhesives: Optical bonding materials (OCA/LOCA).

– Controllers & Electronics: Touch controller ICs, cables, sensors.

– Cutting: Glass is cut to precise dimensions (CNC or laser).

– Edge Grinding / Bevelling: Smooth edges to prevent chipping and improve safety.

– Polishing: Optical-grade surface preparation.

– Cleaning: Ultrasonic cleaning or deionized water baths to remove particles.

– Chemical Strengthening: Ion exchange process (e.g., Gorilla Glass) to increase durability.

– Thermal Tempering: Heat treatment to enhance impact resistance.

– Surface Coatings:

1. Anti-Reflective (AR)

2. Anti-Glare (AG)

3. Anti-Fingerprint (AF/oleophobic)

4. UV/IR filtering

– Silk-Screen Printing: Decorative border printing using ceramic ink, then fired for durability.

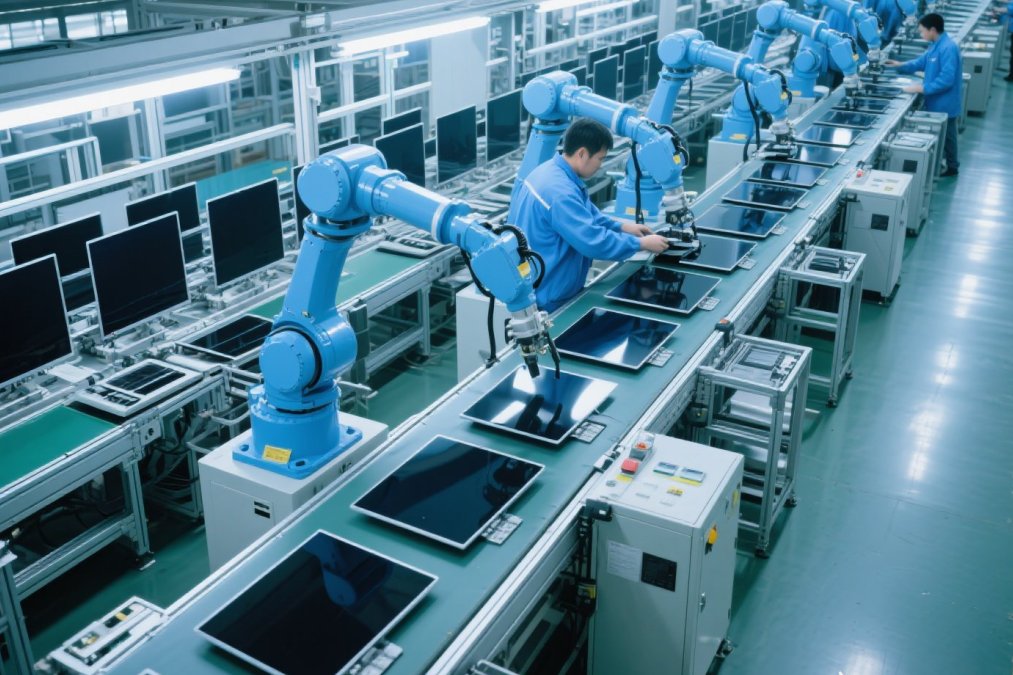

– ITO Deposition: Indium Tin Oxide applied via sputtering or coating for capacitive sensing.

– Photolithography / Etching: Defines the sensor matrix on the glass.

– Laser Patterning: Alternative to photolithography for sensor traces.

– Metal Mesh or Nano-Wire Deposition (for large format or high-res touchscreens)

– Lamination: Sensor + cover glass + other layers are laminated using:

1. OCA (Optically Clear Adhesive) or

2. LOCA (Liquid Optical Clear Adhesive)

– Vacuum Lamination: Eliminates bubbles and improves bonding uniformity.

– UV Curing / Heat Curing: Final hardening of adhesives.

– Visual Inspection: For scratches, chips, bubbles, coating defects.

– Dimensional Measurement: Tolerance checks with digital callipers or CMMs.

– Electrical Testing: Continuity and resistance checks; Touch sensitivity and accuracy; Linearity and ghosting

– Optical Testing: Transmission rate; Haze and reflectivity; Polarizer alignment (if present)

– Environmental Testing: Thermal cycling; Humidity exposure; UV exposure

– Mechanical Testing: Drop test / impact resistance; Surface hardness (e.g., pencil test, Mohs scale); Adhesion tests (for bonded units)

– Functional Testing: Multi-touch capability; Gesture response; EMI/ESD testing

– Integration of touchscreen with LCD, backlight, and enclosure (if applicable).

– Final electrical connectivity and calibration.

– Packaging for shipment with anti-static and shock-resistant materials.

– QC Reports: Batch testing records, certificates of conformity.

– Traceability Tags: Serial numbers, manufacturing dates, batch IDs.

– Packaging: Dust- and shock-proof packaging, especially for high-end industrial panels.

As you can see, touchscreen manufacturing is a highly intricate process that combines precision engineering, advanced materials, and rigorous quality control at every stage. From the initial design concept to final packaging, every step plays a crucial role in delivering a reliable, high-performance product.

MICRON delivers cutting-edge solutions based on copper metal mesh technology, including touch films, transparent antennas, transparent heating films, and EMI shielding films. Holding over 60% of global patents in metal mesh technology, we are committed to innovation, backed by a dedicated R&D team and stringent quality control to ensure product durability and reliability.

Whether you’re developing a bespoke industrial touchscreen, a retail solution, or a next-gen user interface, MICRON has the experience, technology, and support to turn your vision into reality.