2025-09-04

In modern electronics, connections need to be compact, reliable, and often flexible. Two solutions that are commonly used are Flat Flexible Cables (FFC) and Flexible Printed Circuits (FPC). At first glance they may look similar—both are thin and bendable—but in reality, they are built differently, serve distinct purposes, and come with their own strengths and limitations.

An FFC, or Flat Flexible Cable, is essentially a flat ribbon cable where parallel copper conductors are laminated between thin layers of plastic film. The conductors usually run in a straight line from one end of the cable to the other, creating simple one-to-one connections. The ends of the cable are often reinforced with a stiffener, which makes it easier to insert into connectors. Because of its straightforward design, FFC is a practical and cost-effective choice when a device requires a thin, bendable link between two boards or components.

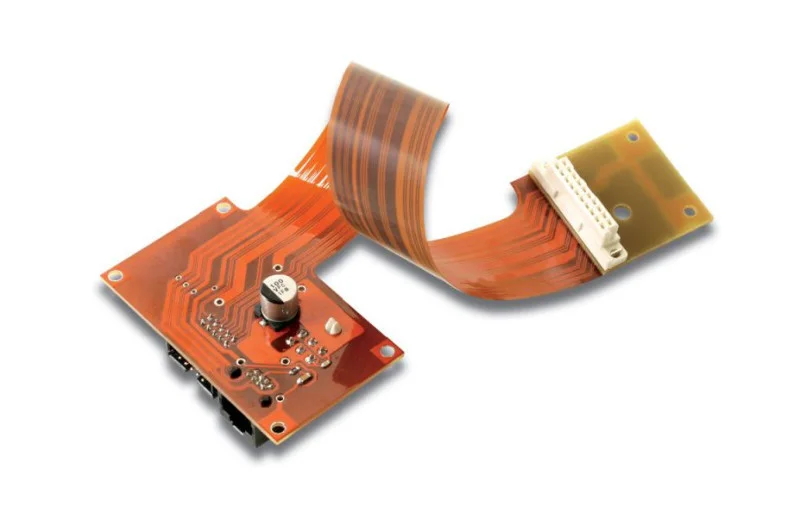

An FPC, or Flexible Printed Circuit, can be thought of as a miniature circuit board made on a flexible base material. Instead of embedding parallel wires in plastic, an FPC is produced by etching or printing copper traces onto a flexible substrate, such as polyimide. These circuits can be single-layer, double-layer, or even multilayer, and they can incorporate complex routing patterns, vias, and sometimes even small components. In essence, while an FFC is a cable, an FPC is a full circuit board with the added benefit of flexibility.

The way FFCs and FPCs are produced highlights their different roles. FFCs are manufactured by laminating flat copper wires between sheets of plastic film and then heat-pressing them together. The exposed copper at the ends is typically tin-plated, and stiffeners are added to make insertion into connectors reliable. This process is relatively simple and lends itself to mass production.

FPCs, on the other hand, are made in a process very similar to printed circuit boards. Manufacturers start with a flexible copper-clad laminate and then remove unwanted copper using photo-etching or chemical methods, leaving behind the designed circuit traces. Multilayer FPCs require stacking and bonding several layers together, with drilled holes to connect traces between layers. A protective coverlay is often applied on top to insulate and protect the copper traces. This process is more complex and allows for customized, high-density circuits.

The physical properties of FFCs and FPCs also reflect their design philosophies. FFCs are slightly thicker, usually ranging from about 0.5 millimeters to over 2 millimeters, depending on the number of conductors. Their layout is always simple and linear, which makes them easy to standardize and reuse.

FPCs, by contrast, are much thinner—often just 0.15 to 0.2 millimeters. They can be shaped to fit unusual contours, bent around corners, or layered to save space. Their flexibility and ability to support complex circuit routing make them ideal for compact and intricate electronic assemblies.

Flat Flexible Cables are most often found in everyday electronics where space is tight but the connection requirements are simple. Common uses include connecting laptop or monitor displays to their controller boards, linking camera sensors to the main circuit board, or enabling movement in printers and scanners. They are also frequently used in appliances and devices with moving panels or hinges because their ribbon-like structure can flex repeatedly without breaking.

Flexible Printed Circuits are used in more advanced applications where both space and circuit complexity matter. They are standard in smartphones, tablets, and wearables, where internal space is extremely limited and dense circuit routing is required. They are also used in automotive electronics, aerospace equipment, and medical devices, where durability, weight reduction, and vibration resistance are critical. In these cases, the FPC is not just a connector but an integral part of the circuit itself.

When it comes to reliability under stress, FPCs generally outperform FFCs. Built on durable polyimide materials and often reinforced with coverlays, FPCs withstand high temperatures, chemical exposure, and constant vibration better than flat cables. Their construction also allows for more flex cycles before failure.

FFCs are durable enough for many consumer and light industrial uses, especially in products where they are flexed moderately, like in laptops or cameras. However, in harsher environments or where long-term durability is a priority, FPCs are the preferred choice.

Cost is one of the clearest dividing lines between the two. FFCs are inexpensive because they are simpler to manufacture, often available in standard sizes, and quick to deploy in designs. They are widely chosen for cost-sensitive products where basic functionality is sufficient.

FPCs, by contrast, are more expensive due to the complexity of their fabrication and the custom design work they often require. Each FPC is usually made to order, tailored to the specific layout and needs of a device. While the upfront investment is higher, the benefits in space savings, reliability, and functionality often justify the cost in advanced products.

Flat Flexible Cables and Flexible Printed Circuits are both essential in modern electronics, but they serve different needs. FFCs are straightforward, affordable, and well-suited for simple board-to-board connections in everyday devices. FPCs are complex, customizable, and more expensive, but they enable high-density, flexible circuits in space-constrained or demanding environments.

Choosing between them comes down to a balance of cost, complexity, space, and durability. For simple, low-cost connections, an FFC is usually the right choice. For advanced, compact, and reliable designs, an FPC is often indispensable.

MICRON delivers cutting-edge solutions based on copper metal mesh technology, including touch films, transparent antennas, transparent heating films, and EMI shielding films. Holding over 60% of global patents in metal mesh technology, we are committed to innovation, backed by a dedicated R&D team and stringent quality control to ensure product durability and reliability.

Metal mesh conductive film is primarily used in FPCs as conductive layers, shielding layers, and touch sensors, playing a key role in foldable displays, wearable devices, sensors, and other fields. Its advantages lie in its high conductivity, high transparency, excellent flexibility, and environmental tolerance, meeting FPC requirements for lightweight, high reliability, and functional integration.