2025-06-04

When choosing a touch screen, the terms AG, AF, and AR can often leave you scratching your head. In simple terms, AG (Anti-Glare), AF (Anti-Fingerprint), and AR (Anti-Reflective) are specialized coatings applied to glass surfaces to optimize both visual quality and touch performance. Because LCD devices are used in so many different environments, users have varying requirements for display clarity and touch responsiveness. A standard protective glass or bare display may not meet all these demands. That’s where choosing the right surface-coating technology becomes crucial. Today, we’ll dive into this topic so you can make a more informed decision.

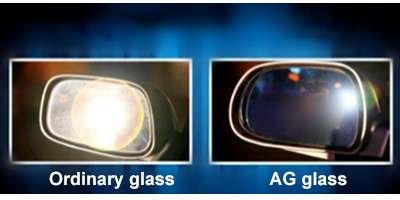

AG (Anti-Glare) coating works by scattering incoming light via a micro-textured surface or embedded scattering particles. This diffusion minimizes mirror-like reflections, making the screen much easier to read in bright or challenging lighting.

In strong light environments, glare can seriously affect visibility, so anti-glare glass is essential. Applications of anti-glare glass in cover glass include:

1. In industrial environments such as factories, glare can interfere with the operation of machines. AG coatings enhance the readability of control panels, thereby improving safety and efficiency. For example, cranes, excavators, environmental monitoring equipment, etc.

2. In operating rooms and other medical environments, clear visibility is essential. AG coatings minimize glare and ensure accurate display of images on diagnostic displays. For example, microscopes, X-ray machines, etc.

3. Sunlight and other strong light can fade images on outdoor displays. AG coatings ensure that content remains clearly visible even under strong light conditions. For example, ATMs, ticket machine digital signage, new energy charging piles, etc.

AF (Anti-Fingerprint) coating creates an ultra-thin, low-surface-energy layer on the glass that repels oil and other residue from fingers, helping the screen stay clean far longer.

Keeps Screens Cleaner, Longer: Because the coating lowers surface energy, fingerprint oils and smudges don’t stick as easily. A quick wipe leaves no residue, so users don’t have to scrub repeatedly.

Sharper Viewing Experience: Smudges and fingerprints can create localized glare or smear out portions of the image. By resisting oils, AF glass keeps visuals crisp and professional-looking.

No Impact on Touch Sensitivity: AF coatings are only a few nanometers thick. They don’t add perceptible thickness or interfere with capacitive touch performance.

Coating Can Wear Over Time: Most AF layers are only tens to a couple of hundred nanometers thick. Frequent cleaning, heavy use, or exposure to high heat can gradually erode that oil-repellent surface—eventually requiring reapplication or panel replacement.

Slight Cost Increase: Applying a specialized low-surface-energy chemistry adds an extra manufacturing step, which translates into a somewhat higher price—especially on large-format displays or bulk orders.

Limited Chemical Resistance: Some harsh solvents (e.g., strong alcohols or bleach-based cleaners) can degrade the AF layer. In those cases, you need to stick with milder, screen-safe cleaning solutions to avoid stripping away the coating.

AF is a must-have wherever frequent touching and a clean look are priorities. Typical uses include:

1. Consumer Electronics: Smartphones, tablets, smartwatches, and other portable devices almost always employ AF glass.

2. Smart Home & Building Controls: As home automation grows, so does demand for smudge-resistant panels—think smart thermostats, touch-panel light controls, smart locks, and even smart mirrors or lighted vanity displays.

3. Public and Commercial Kiosks: ATMs, self-ordering restaurant screens, digital advertising boards, ticketing kiosks—any public-facing touchscreen benefits from AF.

4. Industrial and Medical Instrumentation: In clean-room or lab-grade equipment where cleanliness is critical, AF glass helps minimize contamination and simplify wipe-downs.

5. Automotive: Modern cars use AF glass on infotainment screens, instrument clusters, and rear-seat entertainment displays so that fingerprints from passengers and drivers are less noticeable.

AR (Anti-Reflective) coating consists of multiple ultra-thin layers of materials with different refractive indices. By carefully controlling each layer’s thickness—often around one-quarter wavelength of visible light—reflections from the air-coating and coating-glass interfaces destructively interfere, dramatically cutting overall surface reflectivity. This lets more light pass through, boosting image brightness and color accuracy.

Higher Light Transmission & Better Color Accuracy: Standard glass can reflect 4–8% of visible light back at you. AR coatings can drop that to less than 0.5%, so more of the display’s output reaches your eyes. Colors look richer, contrast is enhanced, and you see deeper blacks.

Improved Readability in Any Lighting: AR glass stays legible under virtually all lighting conditions—especially outdoors under bright sun—because it minimizes those distracting specular reflections.

Compatibility with AG: Some premium AR processes incorporate gentle matte textures or nano-patterning that combine anti-reflective and anti-glare properties, giving the best of both worlds without the usual tradeoffs.

Higher Cost: Creating precise multi-layer stacks often requires vacuum deposition or sputter-coating equipment—expensive capital investments. That makes AR-treated glass at least 30–50% more expensive than plain glass, depending on quality and brand.

Angle-Dependent Performance: Traditional single-band AR coatings work best around a specific wavelength range and incidence angle (usually near normal incidence). When you tilt the screen or view at an angle, you may see slight color shifts or increased reflectance unless you upgrade to a “broadband” or multi-angle design—at even higher cost.

Careful Cleaning Required: The ultra-thin layers can be more sensitive to abrasive cleaning or harsh chemicals. You’ll need to use a lint-free microfiber cloth and a mild, pH-neutral cleaner to prevent micro-scratches or coating delamination.

For any application where peak clarity and minimal reflection matter, AR glass is a game changer:

1. High-End Displays: Premium monitors, TVs, laptops, tablets, phones, and e-readers often employ AR layers so users see the screen exactly as intended—vibrant colors, deep contrast, and no washed-out glare. In automotive and aviation, AR glass is used on navigation displays and instrument panels to keep information clear in bright environments.

2. Optical Instruments: Camera lenses, microscopes, telescopes, and even solar panel protective glass leverage AR coatings to maximize light throughput and minimize stray reflections inside the optics.

3. Professional Medical and Industrial Equipment: Diagnostic monitors, endoscopy displays, or any medical instrument where visualization accuracy directly impacts patient care. Likewise, AR is valuable on industrial control panels and measurement devices (e.g., spectrometers, high-precision scanners).

4. Other Uses: From high-end photo printers to luxury retail signage and LED backlight modules, AR films deliver a polished look and functional advantage by letting true colors and fine details shine without mirror-like disruptions.

Although AG, AF, and AR serve different purposes, it’s common to combine them for a superior overall experience:

AG + AR

This pairing cuts both glare and reflection—ideal for outdoor digital kiosks or tablets used in bright sunlight.

AR + AF

Gives you crystal-clear viewing (thanks to AR) plus a smudge-resistant, easy-clean surface (thanks to AF). Perfect for high-end smartphones, tablets, or medical displays.

AG + AF

Reduces harsh glare and keeps fingerprints at bay—frequently used in point-of-sale terminals, industrial touch panels, or any device in an environment where bright lights meet heavy finger traffic.

AG + AR + AF

When budget allows, combining all three offers the ultimate in visual clarity, low reflection, and easy maintenance—making it ideal for flagship consumer devices, critical medical monitors, or outdoor industrial displays in demanding environments.

Choosing the right glass coating process requires a combination of usage scenarios, functional requirements, and budget. So after fully understanding the differences between AG, AF, and AR coatings, you can confidently evaluate various touch glass solutions and choose the best solution for your next display purchase.