2025-07-23

With the continuous development of smart electronics, photovoltaic technology, and new display industries, the demand for high-performance transparent conductive materials is growing rapidly. Metal Mesh conductive films, as one of the alternatives to ITO (indium tin oxide), are becoming an ideal choice for many cutting-edge applications due to their excellent conductivity, transparency, and flexibility.

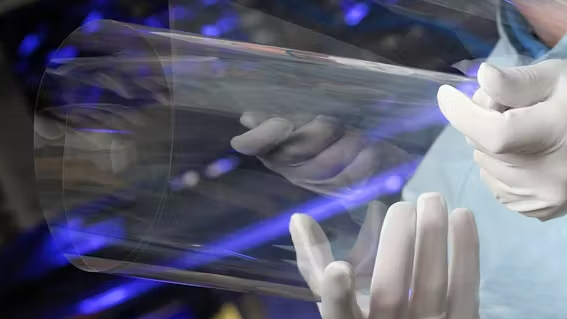

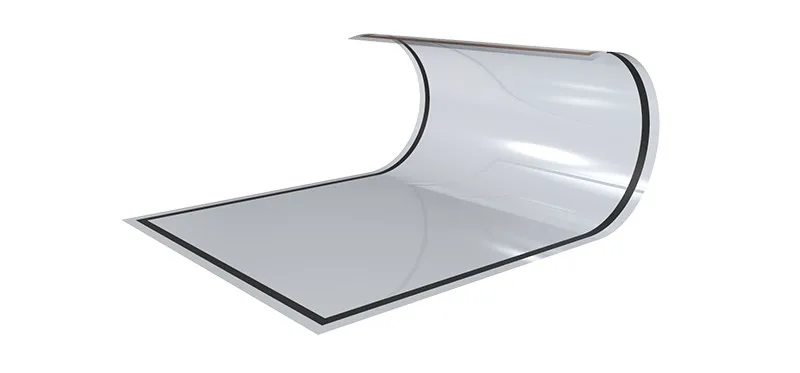

A metal mesh conductive film is a type of transparent conductive film material constructed by forming a micro-scale metallic grid pattern on a transparent substrate. This grid structure provides excellent electrical conductivity while maintaining high light transmittance. It is widely used in touchscreens, organic photovoltaics (OPV), transparent heating films, transparent antennas, and more.

Compared to traditional indium tin oxide (ITO), Metal Mesh exhibits superior conductivity, mechanical flexibility, and processing compatibility, making it especially suitable for bendable or large-sized devices.

1. Metal Grid Structure Design

The metal grid is the core component of Metal Mesh, where the grid lines act as conductive pathways. These grid patterns can be designed in squares, hexagons, or other geometric shapes. Key parameters of the grid include:

In different application scenarios, it is necessary to balance the trade-off between conductivity and transparency by reasonably designing grid parameters. For example, in touchscreen applications, the line width and spacing must ensure both good conductivity for touch signal transmission and high transmittance for display clarity.

2. Substrate Materials

The substrate provides structural support for the metal grid. For flexible electronic devices, flexible plastic films are typically chosen as substrates to enable bending and stretching. Common flexible substrates include PET (polyethylene terephthalate), COP (cyclic olefin polymer), and PC (polycarbonate), each with unique properties such as thickness, heat resistance, and flexibility.

For applications requiring high flatness and hardness, glass substrates are more suitable.

MICRON specializes in ultra-fine copper metal mesh (Metal Mesh) technology, forming grid structures with microscale metal traces to ensure high transmittance in transparent areas while achieving extremely low resistance.

Our copper metal mesh films typically feature:

– High Transmittance: Achieved via fine-line patterning, ideal for transparent/visible applications.

– Low Sheet Resistance: Enabled by high-aspect-ratio traces.

– Flexibility/Bendability: Realized through film substrates and fine patterning.

– Wide Operating Temperature Range: -85°C to +85°C.

– High Design Freedom: Customizable grid designs based on application needs.

The performance of metal mesh conductive films depends on material properties, structural design, and manufacturing processes. By scientifically balancing parameters and processes, conductivity, transmittance, and mechanical properties can be optimized for diverse applications.

As a leader in this field, Zhiling Weiye has successfully applied Metal Mesh copper films in high-end sectors like touch displays, flexible electronics, automotive screens, and EMI shielding, driving industry innovation with outstanding performance.

For detailed application cases or sample requests, please feel free to contact us!