2022-08-11

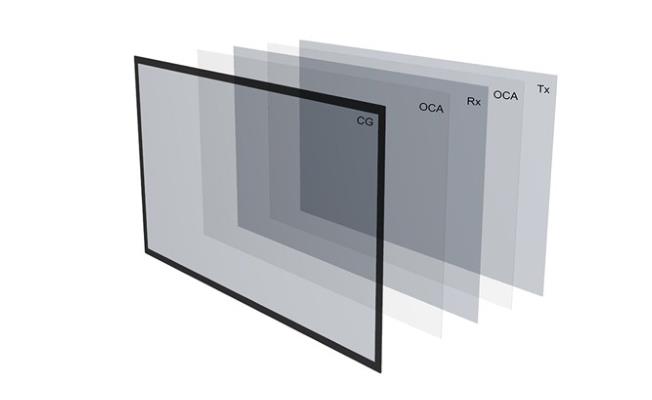

Through the use of several bonding methods, classic optical bonding technology enables the integration of a touch sensor, cover glass, and display into a single unit. We provide hybrid bonding as one of the most advanced bonding technologies in addition to the traditional bonding techniques. Under UV light, LOCA bonding is cured and appropriate for cover glass, SITO Touch, or display connections (hard-to-hard). Applying the film touch sensor to the cover glass is done via a process known as “film bonding” or “OCA roll laminating” (hard-to-soft). A more advanced combination of the LOCA and OCA procedures, hybrid bonding is especially well suited for high-volume applications.

The touchscreen glass is adhered to the LCD cell via optical bonding to entirely cover the space between them. This is done to increase overall performance, reduce the weight of the entire display, and strengthen the touchscreen. Interactive displays are often fastened to LCD cells via the edges of the screen glass with adhesive tape. No matter how small the air gap may be, doing this generates one between the LCD cell and the screen glass that is harmful to the display’s functionality. There are drawbacks as a result of the gap, including weaker screen glass, less touch sensitivity, and a smaller viewing angle, among others.

Due to the hardened adhesive acting as a shock absorber beneath the glass, the optical bonding procedure offers improved shock protection for both the cover glass and LCD cell. Internal reflections that occur between the LCD unit and the screen glass can be eliminated by optically bonding the display. Contrast is increased, making it easier to view the display in brighter settings. In addition, by eliminating internal reflections, a wider viewing angle is created, improving the clarity of the display in larger spaces.

The internal reflection that occurs between the LCD cell and the screen glass is eliminated with an optically bonded display. As a result, the contrast is increased, making it easier to view the display in brighter settings. Additionally, by removing internal reflection, a broader viewing angle is created, improving the clarity of the display in larger spaces. Everyone will be able to see the screen clearly and without reflection, regardless of whether you have student desks in the front corners of the classroom or have to squeeze chairs up the front edges of the meeting room.

Enhanced touch performance:

Depending on your line of sight, parallax, or the angle at which light refracts, causes a pen or finger to appear to be physically located at a different place than the corresponding point on the LCD. Optical bonding decreases parallax. As a result, there is inaccurate touch and a bad user experience. By eliminating the air gap and parallax, optical bonding gives you the most precise touch and the most trustworthy and natural experience.

As a result of the air gap being eliminated between the cover glass and LCD panel, condensation cannot form on the inner surface of the glass as a result of dust and moisture penetrating the glass. This is crucial in humid conditions because prolonged exposure to high humidity can result in display fogging on non-optically bonded devices. Additionally, it is crucial for storage and shipping, guaranteeing that the displays last a lot longer in their ideal condition.

The cover glass can be thinner thanks to the optical bonding technique since it is supported by a layer of firm glue. This considerably reduces the display’s overall weight, making it lighter and simpler to handle and move.

The only true bonding is optical bonding. Despite claims to the contrary, only an optically bonded display can legitimately be said to be bonded. Other techniques are identical to the air bonding procedure in that they employ a tape to secure the LED cell to the glass, which always results in an air gap. Only an optically bonded display is able to totally eliminate the air gap and offer all of these advantages.

Although optical bonding is frequently used in high-end smartphones, using this technology on bigger panels, such as interactive displays, is more challenging. In order to evenly bind screens and provide optically bonded displays, Newline Interactive uses the most cutting-edge optical bonding technology.

Classic Optical bonding technology methods:

LOCA bonding:

The touch/TFT panel is then attached using the LOCA procedure after the cover glass has been dispersed with liquid adhesive. The glue then spreads across the components without creating any bubbles. After that, UV light cures the glue without producing much heat. By doing this, the material is shielded from heat and mechanical impact. One of the most well-known and established technologies is the LOCA process. The bonding of hard materials like glass, plastic, and TFT panels is particularly well suited to it.

OCA bonding:

The OCA technique employs a roll lamination system to adhere the touch sensor to the cover glass using an adhesive layer on a touch film carrier. Finally, an autoclave is used to eliminate inclusions like air bubbles. EMC, UV, and protective coatings can be directly applied to the cover glass or sensor using this method.

Gel bonding:

Gel bonding involves utilizing a gel pad to affix the display and touch unit together. The pads are trimmed to meet the display’s size and shape in terms of their width, height, and thickness. The pad is then rolled laminated onto the touch unit and fused to a frameless display. The touch display device is then put together in a vacuum that has been produced artificially. This method works especially well for bonding displays that have thin or no frames.

To bind touch sensors to glass as well as to bond glass or touch sensors to screens, hybrid bonding combines the benefits of the LOCA and OCA methods. To begin, a precise amount of liquid glue is first applied to the surface that has to be joined. Next, UV light is used to pre-cure the adhesive. Following that, the parts are precisely positioned and vacuum-bonded together. UV light is then used to fully cure the adhesive layer. We have integrated this technology into a highly productive, completely automated process that allows us to build touch glass display solutions at scale.

Touchscreen displays have been around since the 1980s but they have not changed much over time. In fact, many people still prefer them because they are easy to use. But there are some new technologies on the horizon that could change everything about touchscreens. Classic Optical bonding technology has made its way back onto smartphones, tablets, and even laptops.

Displays:

A new generation of displays has arrived, bringing together the best of both worlds great image quality and energy efficiency. In order to provide users with the best experience on their devices, we have created a new product line called Smart Displays. These are designed to be a seamless extension of your smartphone or table. They work like a second screen, only better. Our classic optical bonding allows our frames to be strong while remaining lightweight and flexible. A highly durable lens protects your eyes from harmful UV rays.

Optical sensor:

Optical Sensor is an innovative new way to measure distance. It uses classic optical bonding technology to create a highly accurate measurement system. Optical sensors are used in many applications where light needs to be detected or measured. They are also used as components in various devices such as cameras, projectors, and mobile phones. Optical sensors are used in digital cameras to convert light rays into electrical signals. It allows you to detect any objects in front of you without having to turn on the light.

Projectors:

Optical bonding technology has made projectors more reliable and easier to use. With the introduction of new technologies, projectors are becoming even better. Projectors are an essential piece of equipment for any business or home. Classic Optical bonding technology is an advanced used by many manufacturers to create high-quality projectors.

This article described the classic optical bonding technology that involves employing an adhesive to fuse two thin layers of glass together. Through this process, a strong bond is formed that is resistant to external factors such as humidity and temperature changes. Displays subjected to extreme environments, such as those seen in industrial or medical environments, often use this type of bonding. MICRON provides you with contemporary, fashionable, perfect, designed for consumers’ demands and deserving of your confidence. The needs of our consumers come first for us. It is beneficial to use in many places. Our goal is to remain a customer for life. On a technological level, we have advanced significantly in a perfect, useful, and beneficial way.