2025-09-11

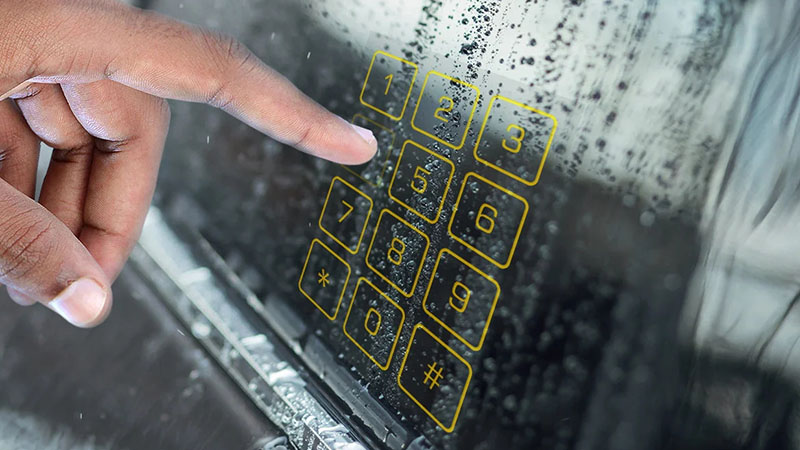

In today’s digital age, touchscreen displays are ubiquitous in devices ranging from smartphones to industrial control systems. However, when it comes to waterproof touchscreens, many wonder: Can these devices truly function underwater? Waterproof ratings like IP67 or IP68 indicate resistance to water immersion, but does the touch functionality hold up as well? This article explores the topic.

Waterproof touchscreens are engineered with protective enclosures and materials to shield internal components from water ingress. The primary benchmark for waterproofing is the Ingress Protection (IP) rating system, established by the International Electrotechnical Commission (IEC). This standard quantifies resistance to solids and liquids:

1- IP65: Offers dust protection and resistance to low-pressure water jets from any direction, suitable for environments with occasional splashes.

2- IP66/IP67: Provides defense against powerful water jets or temporary immersion (e.g., up to 1 meter deep for 30 minutes), ideal for humid industrial settings.

3- IP68: Enables prolonged immersion at greater depths, designed for more severe conditions like submersion.

These ratings emphasize structural integrity, ensuring water does not penetrate the housing or sensor layers. However, achieving waterproofing involves more than just seals; it requires integrating hydrophobic coatings, gaskets, and robust adhesives to maintain functionality under stress. The design must also account for pressure differentials that could compromise seals during immersion.

The dominant technology in touchscreens is Projected Capacitive (PCAP), which relies on a grid of microscopic electrodes embedded in the glass or film layers. When a conductive object, like a finger, approaches the surface, it disrupts the electrostatic field, altering capacitance and registering a touch event. This self-capacitive or mutual-capacitive detection allows for multi-touch gestures with high precision in dry conditions.

In waterproof scenarios, the challenge arises from water’s properties as a conductor. Even surface moisture can mimic finger capacitance, creating unintended signals. For true waterproofing, the system incorporates:

1. Sealed Sensor Layers: Transparent conductive materials like Indium Tin Oxide (ITO) are layered with insulating films to isolate electrodes from external liquids.

2. Hydrophobic Surfaces: Treatments that repel water reduce droplet accumulation, minimizing interference by promoting quick evaporation or runoff.

3. Grounding and Shielding: Internal grounding planes absorb stray currents from water, preventing electrical shorts.

These elements ensure the display remains visible and the electronics protected, but they do not inherently solve touch detection issues in fully wet states.

Despite robust designs, waterproof touchscreens encounter significant hurdles, especially underwater:

1. Conductive Interference: Water’s high electrical conductivity bridges the electrode grid, flooding the system with false capacitance changes. This leads to “ghost touches,” erratic inputs, or complete unresponsiveness, as the signal-to-noise ratio plummets.

2. Immersion Effects: Submersion introduces uniform conductivity around the screen, overwhelming the localized field changes needed for accurate detection. Depth-related pressure can also flex materials, potentially creating micro-gaps in seals.

3. Environmental Factors: Saltwater accelerates corrosion of conductive layers, while temperature fluctuations (e.g., cold water contracting seals) exacerbate leaks. Flowing water or bubbles can cause dynamic interference, further degrading performance.

Testing reveals that standard PCAP touchscreens often fail in submerged tests beyond brief exposure, highlighting the gap between hardware waterproofing and interactive usability. Lifespan is another concern; repeated wet-dry cycles can degrade adhesives and coatings, reducing overall durability.

Technological progress is bridging these gaps through refined engineering and alternative approaches:

1. Water-Rejection Algorithms: Software enhancements in PCAP controllers analyze signal patterns to distinguish genuine touches from water-induced noise. These algorithms use machine learning to filter interference, enabling reliable wet-finger operation and rapid recovery after submersion.

2. Enhanced Materials and Coatings: Advanced nanomaterials, such as oleophobic layers, improve water shedding and reduce surface tension. Multi-layer sensor designs with differential sensing amplify true touches while suppressing uniform water effects.

3. Alternative Sensing Methods: To overcome capacitive limitations, hybrid systems integrate resistive or surface acoustic wave (SAW) technologies, which detect pressure or vibrations rather than conductivity. Optical or infrared sensors, which use light beams unaffected by water, offer promise for deep immersion without electrical interference.

4. Integrated Waterproofing Standards: Modern designs incorporate comprehensive testing protocols, including salt fog exposure and pressure chamber simulations, to verify performance across real-world variables.

These developments have extended waterproof touchscreens to depths of several meters for limited durations, with ongoing research focusing on haptic feedback for confirmation in noisy environments.

Waterproof touchscreens are applied in diverse fields requiring moisture resistance. The following table outlines general scenarios, highlighting technical considerations:

| Application Area | Typical Use Case | Key Technical Features | Common Limitations |

|---|---|---|---|

| Marine Environments | Navigation interfaces on vessels | IP67+ sealing with anti-fog coatings | Reduced precision in heavy spray or waves |

| Industrial Settings | Control panels in wet processing areas | Hydrophobic surfaces for glove use | Corrosion risk from chemicals or saltwater |

| Outdoor Equipment | Handheld devices for fieldwork | Pressure-resistant enclosures | Battery drain from constant signal processing |

| Medical Devices | Hygiene-focused interfaces in labs | Antimicrobial waterproof layers | Sensitivity loss with thick gloves or residues |

| Consumer Gadgets | Wearables for water sports | Compact SAW hybrids for submersion | Limited multi-touch in dynamic water flow |

In each case, the technology prioritizes reliability over full dry-condition performance, often requiring user training on adapted gestures.

Waterproof touchscreen technology balances materials, electronics, and software to counter water’s interference with capacitive sensing. IP ratings provide protection, but innovations in algorithms, coatings, and hybrid sensors address ongoing challenges like noise and degradation. As research advances, these systems will offer more intuitive interactions in demanding wet environments.