2025-07-29

When we talk about a TFT touch display, we’re referring to a thin‑film transistor liquid‑crystal display (TFT‑LCD) that is integrated with touch‑sensing capability. TFT technology uses tiny transistors for every pixel, yielding vivid, full‑color imagery with faster refresh rates and sharper contrast compared to older passive matrix LCDs. The “touch” part typically involves either capacitive or resistive layers stacked atop the LCD panel, enabling users to interact directly with the content.

TFT displays emerged in the 1970s and matured into active‑matrix LCDs by the early 1980s. Their key advantage was individual pixel control via transistors, which eliminated ghosting and allowed for video‑speed updates. Today TFT‑LCD remains the dominant mainstream display technology, especially in sizes from 1.3″ up to around 10″, commonly seen in microcontroller kits and embedded systems.

Adding touch capability transforms these displays into interactive panels. There are two primary touch technologies: resistive touch uses pressure to bring two conductive layers together, registering a touch accurately even when wearing gloves or using a stylus. Conversely, capacitive touch relies on detecting the electrical charge of a fingertip, enabling multi‑touch gestures—swipes, pinches, taps—on a transparent conductive grid such as indium tin oxide (ITO) layered over the screen.

Capacitive TFT touch modules typically combine:

– A capacitive touch panel (cover glass + sensor grid),

– A dedicated touch controller (via I²C or USB interface),

– The TFT LCD module itself, with backlight and display driver.

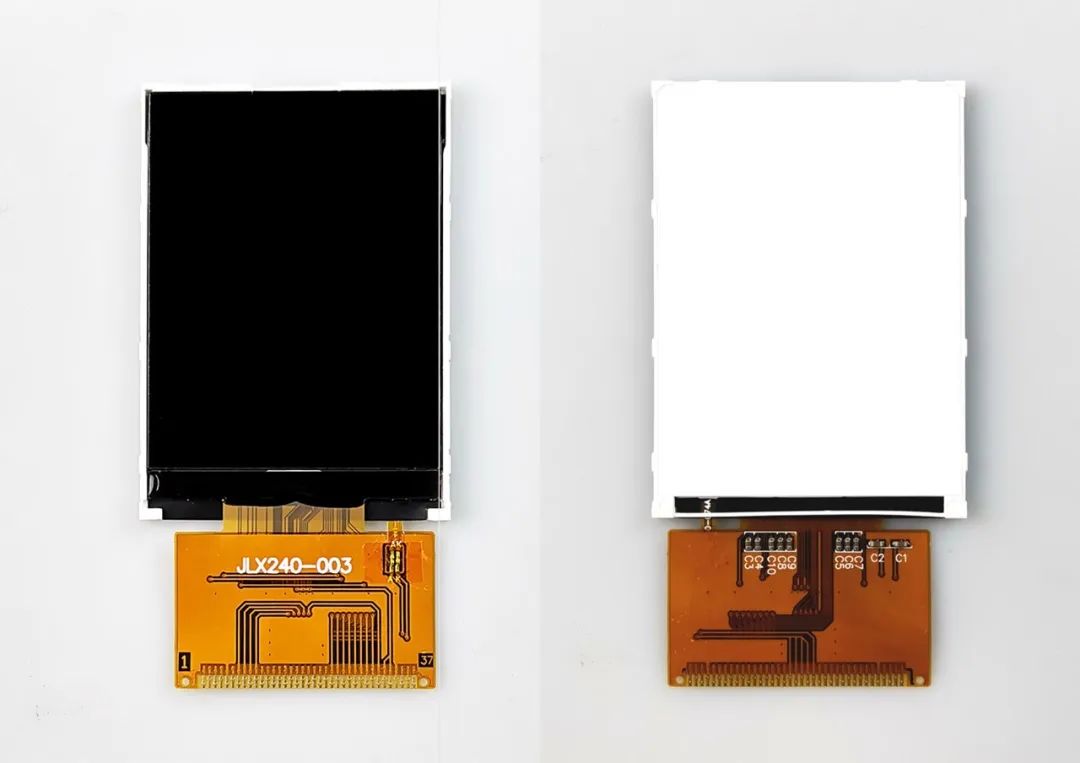

There are two main integration methods: frame bonding, which attaches the touch layer at the edges with adhesive, and optical bonding, which fully laminates the layers with optical clear adhesive (OCA) to reduce reflections and improve durability. Some advanced designs implement One Glass Solution (OGS), where the touch sensors are applied directly onto the cover glass or LCD cell itself—cutting thickness and cost while enhancing clarity.

The appeal of this technology lies in its combination of reliable color quality, touch interactivity, and wide availability across many sizes and interfaces. It delivers:

– Rich visuals with high pixel density and vivid color,

– Responsive touch control, including multi‑touch gestures in capacitive variants,

– Versatility—use it in DIY electronics, industrial monitors, and consumer gadgets alike,

– Cost efficiency, especially in standard sizes and well‑established manufacturing processes.

In many industrial, medical, or rugged settings, resistive touch displays are preferred due to their durability and ability to work with gloves or styluses. However, for consumer devices or applications needing intuitive gestures, capacitive TFT displays offer a smoother, multi‑touch experience, albeit with slightly higher cost and sensitivity to moisture or certain gloves.

The marriage of TFT visuals and touch interaction has become ubiquitous in smartphones, tablets, ATMs, industrial control panels, automotive infotainment systems—anywhere we expect vibrant screens with direct user engagement. In embedded electronics, hobbyists and DIY engineers commonly use modules like 2.8″–4.3″ SPI‑interfaced TFT capacitive screens with microcontrollers (Arduino, Raspberry Pi) for prototyping colorful.

Innovations like flexible TFT panels—some even made using silk-based insulating films—are opening new form factors for foldable devices and wearable screens. Optical bonding and OGS strategies are pushing slimmer, glare‑free modules.

In addition, capacitive sensors are improving to support gesture recognition and even glove‑compatible touch. These developments are shaping a future where TFT touch displays are thinner, brighter, and more seamlessly interactive.

Combining TFT and touch technology—whether resistive or capacitive—creates versatile interfaces that are both visually rich and powerfully interactive. Together, TFT touch displays strike a balance between image quality, responsiveness, cost, and durability—making them a smart option across consumer, industrial, and embedded applications.

MICRON delivers cutting-edge solutions based on copper metal mesh technology, including touch films, transparent antennas, transparent heating films, and EMI shielding films. Holding over 60% of global patents in metal mesh technology, we are committed to innovation, backed by a dedicated R&D team and stringent quality control to ensure product durability and reliability.

As a trusted supplier to leading global touch device manufacturers, MICRON has established subsidiaries in countries such as the United States and Japan to provide timely and efficient services worldwide, ensuring seamless support for our international clients.